Beyond

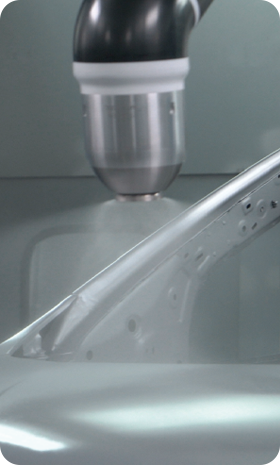

Your Dream 두림야스카와의 로봇 자동화 기술은 단순히 생산성을 높이는 것을 넘어, 고객의 꿈과 가치를 실현하는 획기적인 도약을 이루어내고 있습니다.

Your Dream 두림야스카와의 로봇 자동화 기술은 단순히 생산성을 높이는 것을 넘어, 고객의 꿈과 가치를 실현하는 획기적인 도약을 이루어내고 있습니다.

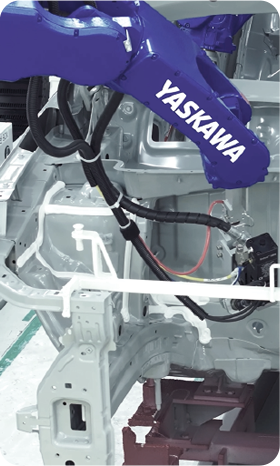

두림야스카와는 야스카와전기의 로봇 자동화 솔루션을 대표하는 시스템 하우스 중 하나입니다.

고객사의 모든 요구를 충족시켜 줄 수 있는 자동화 파트너가 되기 위해 노력합니다.

언제나 고객과 소통하는 두림야스카와 입니다.